Used Natoli Tablet Press Machine – NP30, Cert by OEM w/Service

$80,000.00

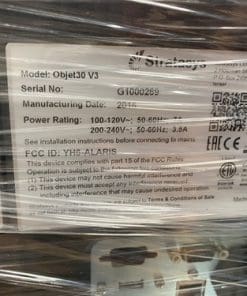

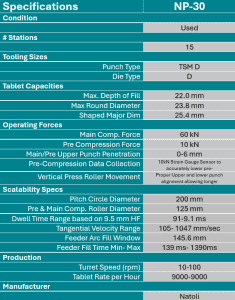

Excellent condition used 15 station tablet press machine. Natoli NP-30, with low hours. It has been certified by the OEM, and comes with a 2 year service agreement. All service records are available. The NP-30 was developed for applications that require multiple products run on the same day. This small to medium batch production press and is easy to learn to operate, easy to clean, change over, and maintain as many companies require in the industry. This pill press machine was manufactured in 2021 with very few run hours on it.

Contact for Quote

Weights/specifications will be provided for shipping.

Out of stock

Service Records available upon request

Natoli NP-30 Tablet Press: 15 D Station

Standard Features:

► Separated Compression Zone

Contains product in the compression area of press

Reduces cleaning Time

Separates the mechanical and product contact areas during operation

Improves press reliability

Extends press life

Compliant with cGMP

► Upper and Lower Punch Seals

Stops formulation from getting on punch barrels

Improves punch life

Reduces heat buildup during production, punch binding, clean-up time and wear on upper and lower turret sections

Stops lubrication from transferring to the die table

Protects punch barrels and punch guides from sticky, corrosive, and abrasive products

► Toolless Self-Adjusting Lower Punch Retailers with Quick Release Function

Helps maintain consistent tablet weight

Stops punches from dropping freely during production or during installation

Reduces time to install lower punches

Reduces tooling and cam wear

► Real Time Micro Adjust Dosing/Weight Control

Weight control is achieved by monitoring tablet weights and adjusting as required

Adding or subtracting weight adjustments are based on the high and low tablet weights

Dosing is real time micro control adjustment to achieve proper tablet weights quickly and maintain the tablet consistence throughout the tablet production run

► Optimized Fill Cam Design

To improve die filling and consistency of tablets, the press is standard with optimized fill cam

design to ensure the lower punch does not drop until fully under the fill window

This design creates even greater pull-down vacuum of the lower punch under the feeder fill opening

This additional vacuum allows formulations to feed at higher speeds because as the press speed

increases, a proportional vacuum effect on the die increases

► Easy Access to Compression and Overload Settings

Pre and main tablet thickness settings can be adjusted while the press is in production

Overload settings are easily adjusted by operator

Max tip force can be entered for each product to help reduce tooling wear and damage from excess force

► NP30 AIM Lite Software

Feedback is displayed on interface

Adjustment for speed of turret

Visual feedback on tablet production

5 levels of security based on job responsibility

Menu-based architecture to allow for easy access Employees to have access to screens required

for their roles

Admin rights allow full control of user accounts

All errors and alarms are stored

Error/alarm/stop/start events are tracked and reported on batch and performance reports

Location & Terms

Includes a 2 year service agreement; includes email and phone support

Terms: F.O.B

Location: Bridgeton, MO

Disclaimer: Midwest Equipment & Solutions strives to provide accurate information, but purchasers are encouraged to verify all details, specifications, and measurements either through their own expertise or by having the equipment inspected by a qualified professional. Any measurements, including shipping weights, are approximations and may be estimated. Midwest Equipment & Solutions is not liable for any errors or omissions in advertising materials, including those found on its website or in quotations and other documents related to the equipment. Prices listed do not include shipping costs. Crating, skidding, and additional packaging services are available upon request. Shipping and logistics services can be arranged at the buyer’s request.

Related products

Storage Solutions

Lab Equipment

Miscellaneous

Miscellaneous

CNC Machines

Miscellaneous